You are in: Home » Technologies » STORAGE

SPIRAL SILO

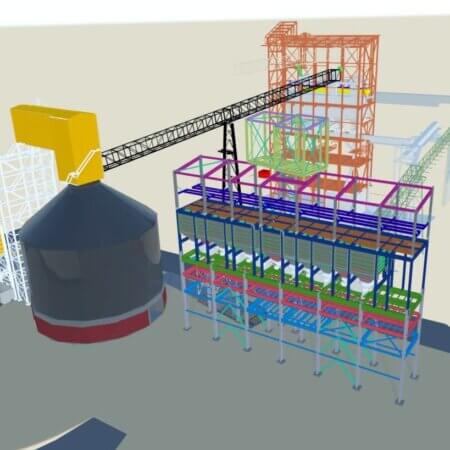

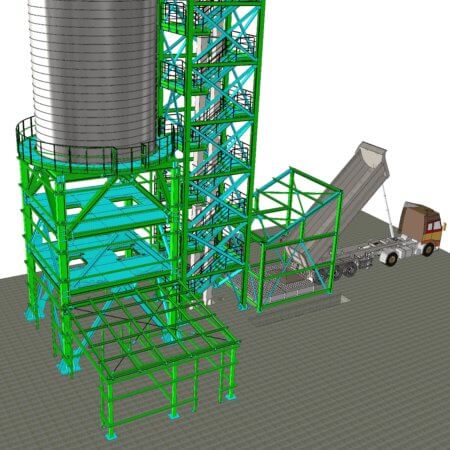

Silos erected directly on site by employing special machines that, thanks to their advanced technology, allow to build cylinders from 2,7 meters to 25 meters of diameter and up to 40 meters high.

This fact enables to exploit the whole space available and assures the most convenient and rational use of the soil.

Thickness of cylinder from 1,5 mm to 4 mm the particular BSP double folding system enables the construction of thicker and stronger silos.

Inside flat smooth wall this is a very important device which avoids stagnation of dust and product (that usually forms in the corrugated plates thus causing proliferation of molds and insects) and which permits a more versatile use.

Absence of bolts on the silo shell so the rust that usually forms on the bolt head (and that extends to the panels) is completely avoided.

Bolts for fixing the roof panels to the cylinder, have been designed in order to be protected against atmospheric conditions.

Any type of metal coils can be used with the BSP spiral system.

All the press bent metallic alloys can also be employed: Inox, Galvanized steel, Black steel, aluminum etc.

Air-water tight system: silo can be totally air/water tight, this advantage allowing to store cereals and liquid products as well.

BENEFITS

- Inside flat smooth wall

- Silos erected direclty on site

- No standardization

- Fast erection

- Gas tight

DOUBLE FOLDING JOINT:

The double fold joint is what makes the BSP silo advantageous.

It runs in a spiral way all around the silo thus bearing all horizontal pressure applied to any part of the structure.

The double fold is completely gas/water-tight

and creates an internal smooth surface free

from grooves and edges.

THE ASSEMBLY

In a very short time an expert a BSP site responsible can start the automated production process by himself.

- After anchoring the mounting ring, a steel coil is placed on the uncoiler reel.

- The steel coil enters the profiling machine, which bends the tape in accordance with the desired diameter of the silo.

- When part of the cylindrical body is erected (2 meters high), the spiral process is stopped to install the roof (as well as outlets, filters, piping, walkways, when foreseen).

- The erection operation starts again and the silo arises up to the desired height.

- When the assembly is finished, the machine turns in the opposite direction, the silo is demounted by the supporting ring and laid down at ground.

- Installing of eventual unloading metallic hoppers or handling equipment.

The complete assembly is achieved very quickly and all the operations are executed at ground level without the employ of dangerous scaffolding.